Installation guide for flue pipes

for wood and pellet stoves

STANDARDS

Chimneys, flues and flue pipes in Europe must bear the CE mark in compliance with Standards EN 1856-1 and EN1856-2, which specify that they must feature designation indicating the product’s characteristics and performance.

National standards (UNI 11278 for Italy) establish the minimum requirements that fireplaces and smoke ducts must have depending on type of use (gas- or wood-fired, wood-burning stoves or pellet stoves, etc…).

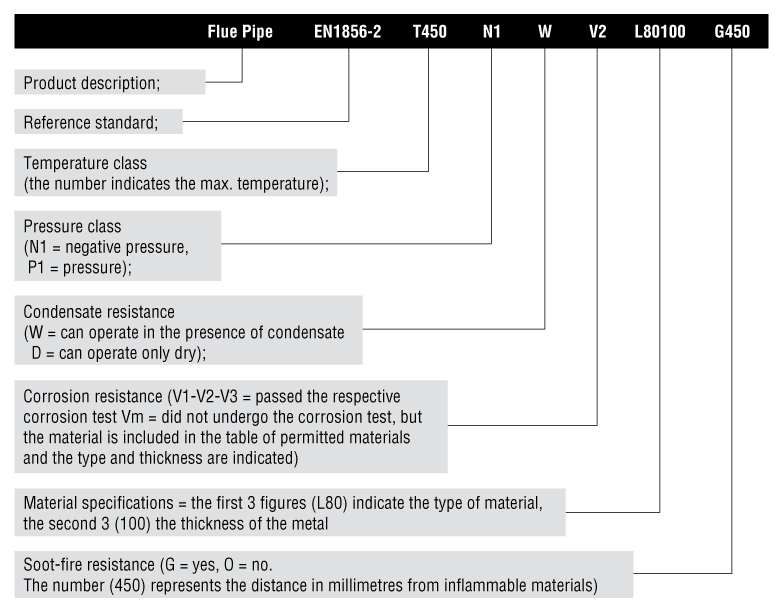

EXAMPLE OF PRODUCT DESIGNATION

AS PER STANDARD EN 1856-2

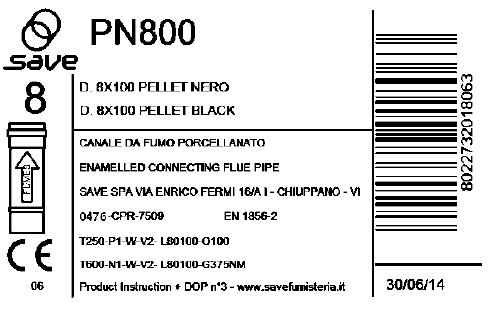

EXAMPLE OF LABEL BEARING PRODUCT DESIGNATION

REQUIREMENTS FOR FLUE PIPES

TO BE INSTALLED IN WOOD OR PELLET STOVES

PERFORMANCE

• FUME TEMPERATUREis much higher than in gas and therefore the class must be at least T400 for wood and T200 for pellet (UNI 11278, Point 6.1);

• SOOTFIRE RESISTANCE

soot fire is the ignition of soot, which is produced primarily by solid fuels, and may develop inside the flue pipe. This type of fire creates extremely high temperatures and for such reason it is necessary and even COMPULSORY TO SELECT CLASS G PRODUCTS (UNI 11278 Point 6.5). In order to obtain Class G rating, the chimney/flue pipe must pass a test that specifies resistance to temperatures of 1000°C for 30 minutes.

Low melting materials (such as ALUMINIUM, with melting temperatures of 600-630°C) CANNOT PASS this test and must therefore be ABSOLUTELY AVOIDED.

Our Classic and Plus line products all have Class G rating and are suitable for use. Our Pellet pipe is also suitable because it has double designation: G, without gasket and O, with gasket. This means that the pipe will prove resistant in case of sootfire and that when necessary only the gaskets must be replaced;

• CORROSION RESISTANCE

Italian Standard UNI 11278 Point 6.4 specifies that the flue pipes installed in solid fuel appliances must pass V2 or V3 corrosion resistance tests. When they pass the test, the test code will be listed in their designation. When they fail to pass the test, “Vm” will appear in the designation, and in this case they must be constructed exclusively in the following materials and with the following minimum thicknesses:

| Material | Code on label | Minimum thickness |

|---|---|---|

| 316L stainless steel | L50 – L60 | 1,0 mm |

| 904L stainless steel | L70 | 0,6 mm |

| Vitreous enamelled steel | L80 | 0,8 mm |

| Normal steel | L01 | 2,0 mm |